A. Basic configuration 1.

Unwind Unit

|

1 unit

|

Max unwind unit diameter 1067mm Pneumatic mandrel unit diameter 3

" 2 units Hydraulic roll shaft lift 1

unit

Magnetic brake system 1 unit

Automatic stopping device when paper

broken Equipped with the fast speed pneumatic gun 2. Automatic web guide system

Splicing table and pneumatic paper pressing equipment 1

unit

Adopts ball screw electric actuator

Adopts the photoelectric sensor for web guide transmission

Electronic web guide traction device.

If there is any excursion in paper feeding, the system will have a constant and

accurate adjustment.

Adopts closed-loop control system to accurately detect the deviation

and correct it. Hard anodization to the paper guide rollers HV800-1000

Inspection: the edge

|

Web guide

precision: ±0.02mm

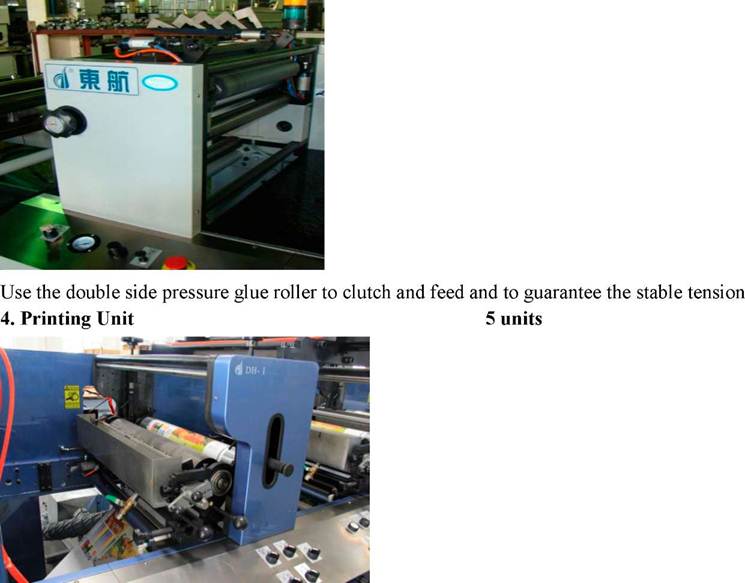

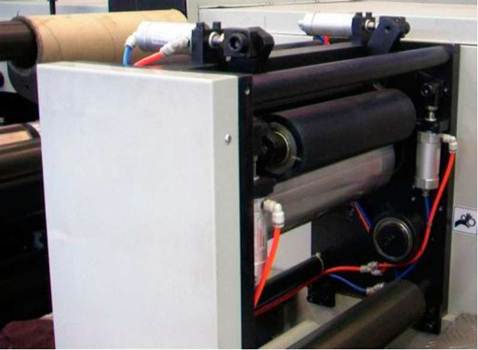

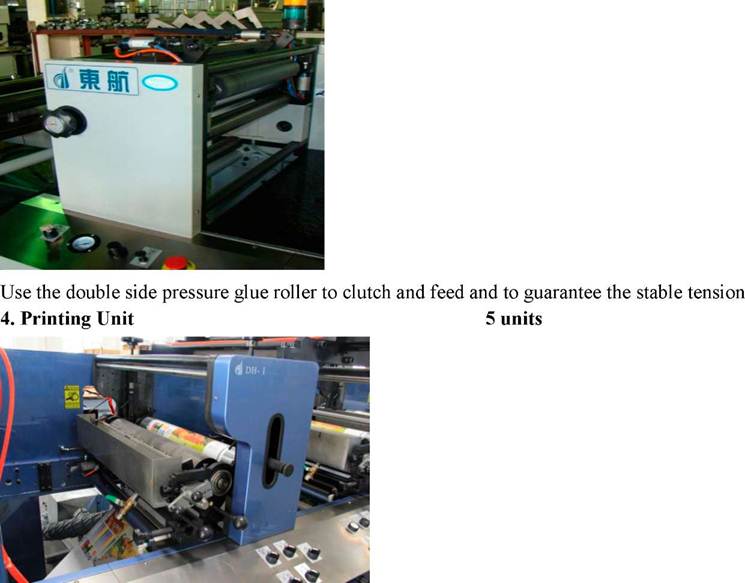

3. In-feed tension control unit

(double side pressure glue roller) 1 unit

|

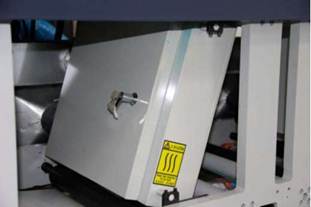

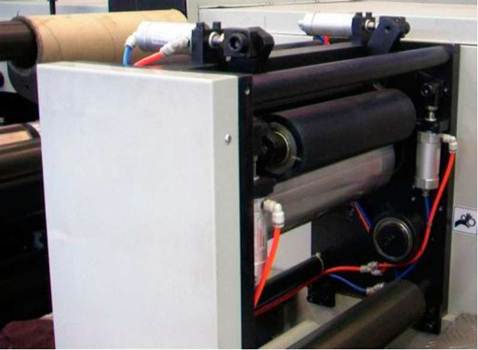

5 printing plate cylinders (repeated length at customer's need) 5

anilox rollers (LPI is according to the customer's products)

Vertical register by manual Horizontal register by manual

Anilox roller and plate cylinder with pneumatic clutch pressure

which can quit automatically Plate cylinders can be changed without any other

tools Automatic cleaning for printing plates

Anilox rollers will continue running after the machine stops to

prevent the ink from drying

Anilox rollers equipped with high precision fine tuning system can

make sure the pressure

between anilox rollers and also plate cylinders

Dance of anilox, plate cylinder and impression cylinder: ^0.03mm

Bearings are P5 degrees

5. Drying system 5 units

I.R. ink drying for each printing unit

Hot air and cooling air combination (including blower)

Volume of air can be adjusted

Tubes from teflon in Korea

There are one air induced draft fan and eight blowers

Waste air will be out by an exhaust fan

6. Synchronous stroboscope still image

inspecting system

Image inspecting camera can take pictures synchronously for the

printing materials. Preset the inspecting position horizontally and vertically.

Zoom the images to have a position inspection.

It can magnify 20 times and observe

the image with a fixed position to guarantee the printing quality.

Installed support equipment and cables High resolution camera

|

14' Philips colorful image inspector 1 unit

High speed flash lamp 1

unit

7. Rear out-feed tension control

system 1 unit

|

Use the double side

pressure glue roller to clutch and feed and to guarantee the stable tension.

8. Rewind

unit 1 unit

Max unwind unit diameter 1067mm Pneumatic mandrel unit diameter 3

" 2 units Hydraulic roll shaft lift 1

unit

Magnetic brake system 1 unit

Automatic stopping device when paper broken Equipped with the fast

speed pneumatic gun

9. Web

cleaner and anti-static unit 1 set

One installed before printing and one after printing

10.

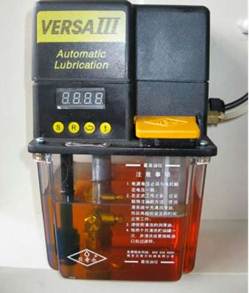

Lubricating system 1

unit

The automatic

lubricating system is adjustable for the lubribating time and amount. When the

system is wrong or it falls short of oil, the alarm light will work.

11. Plate mounting machine 1

unit

It has a screen including the bilateral symmetrical split-screen

display

It is used for the plate mounting to realize the purpose of

multi-color overprinting. Quickly

changes the printing plates

12. Tool kits 1

unit

|

B. The main technical parameters and the functions

|

|

No.

|

Descriptions of Functions

|

Parameters

|

|

1

|

Maximum unwinding diameter

|

1067mm

|

|

2

|

Maximum rewinding diameter

|

1067mm

|

|

3

|

Printing repeat length

|

190 mm—650mm

|

|

4

|

Maximum substrate width

|

660mm

|

|

5

|

Maximum printing width

|

650mm

|

|

6

|

Main motor power

|

11KW

|

|

7

|

Power requirement

|

380V 3PH 50Hz

|

|

8

|

Machine rating speed

|

0— 150Meters/Minute

|

|

9

|

Printing plate thickness

|

1.7mm

|

|

10

|

Printing plate attaching tape thickness

|

0.38mm

|

|

11

|

Substrates thickness

|

At customer's need and confirmed by donghang

|

|

12

|

Register precision

|

±0.1mm

when machine runs steady at a certain speed

±0.13mm when machine speed increases from 10m/min to 150m/min

±0.13mm when machine speed decreases from 150m/min to 10m/min

|

|

13

|

Gears

|

1/8 CP and gear distances 3.175mm

|

|

14

|

Automatic stop when paper broken

|

YES

|

|

15

|

Automatic alert when paper less

|

YES

|

|

16

|

Automatic stop when setting task fulfilled

|

YES

|

|

17

|

Meter counting and quantity counting

|

YES

|

|

18

|

Speed adjustment in many stages

|

YES

|

|

19

|

Automatic register system

|

YES

|

|

20

|

Machine colors

|

Decided by customer

|

|

|

|

C. Main Electrical Parts Suppliers for Donghang Series

Flexographic Printing

|

|

Press

|

|

|

No.

|

Name of product

|

Supplier

|

|

1

|

Rewinder tension inverter

|

Huichuan Shenzhen China

|

|

2

|

Web guide system

|

ST Italy

|

|

3

|

PLC

|

LG South Korea

|

|

4

|

Text display

|

LG South Korea

|

|

5

|

Switch power

|

Mingwei Taiwan China

|

|

6

|

Electric relay

|

LG South Korea or Omelo Japan

|

|

7

|

Circuit breaker

|

LG South Korea

|

|

8

|

Circuit connector

|

LG South Korea

|

|

9

|

Terminal

|

Phoenix Germany

|

|

10

|

Control Button

|

Fuji Japan

|

|

11

|

Aviation plug

|

Weipu electricals

|

|

12

|

Photo-electricity sensor

|

Omelo Japan or Turck Germany

|

|

13

|

Proximity Switch sensor

|

Turck Germany

|

|

14

|

Anti-static

|

Miki technology from UK

|

|

15

|

Auto Lubricating

|

Bijur, China and America joint venture

|

|

16

|

Synchronous Stroboscope

|

Kesai

|

|

17

|

Anilox roller

|

Shanghai

|

|

18

|

Anilox single direction bearing

|

Japan

|

|

19

|

Deep Groove Ball Bearing

|

NSK, Japan

|

|

20

|

High precision epicyclic gearbox

|

Shampo, Japan

|

|

21

|

Automatic register system

|

Kesai

|

|

22

|

Air parts

|

Airtek, Taiwan

|